Product Details:

Payment & Shipping Terms:

|

| Cylinder: | 100ml Or 250ml | Working Position: | 1 Or 2 Or 3 |

|---|---|---|---|

| Operation: | Button Control |

1. Overview

Powder density is corresponding mass in unit volume. Powder density is usually smaller than its real density due to gap among or inside particles. It is divided into apparent density and tap density by different test methods. Apparent density is obtained by evenly and continuously loading measuring cup in identified volume with bulk powder, weigh cup and powder to calculate apparent density. Tap density is measured only after tapping bulk powder under certain requirements.

BHY-100 complies with all requirements of EP Chapter 2.9.15, USP Chapter 616 Method 2 and ISO3953 Metallic Powders-Determination of Tap Density.

It comprises speed-adjustable motor, vibrating assembly, membrane keypad, and micro-computer and BHY-100 Tap density tester features compact structure, robustness and easy operation.

3. International Norms & Definitions

3.1 ISO 3953 Metallic powders-Determination of tap density ISO 3953:2011 specifies a method for the determination of tap density, i.e. the density of a powder that has been tapped into a container under specified conditions.

3.2 USP 616 Tapped density Method II

3.3 HYTM B 527

3.4 DIN ISO EN 787/11

3.5 EP 2.9.15

3.6 No: Reference number of the test.

3.7 Weight: weight of the powder

3.8 Volume: volume of the powder

3.9 Tap Num: tap number of the test

3.10 Result: test result

3.11 TAP NUM: tap number

3.12 START: start test

3.13 STOP: Stop tapping before obtaining a result. Test report only shows the actual tap numbers. In the absence of re-setting "TAP NUM", press "START" button, the system continues the remaining tap.

3.14 NO. Reference number of the test

3.15 WT: weight of the powder

3.16 VOL: volume of the powder

3.17 "→": Remove the lt bit of data just entered.

3.18 CE: restore the system to boot state, all data is restored to the status before pressing OK

3.19 CAL: calculate on data obtained

3.20 PRINT: print test report

3.21 OK: save "TAP NUM," "WT", "VOL", "No." Operator needn't input again when he test again if he does not change anything. Re-test samples, such HY some of the data has not changed, the need to re-enter the data. "No." is automatically increased by 1 after each calculation.

4. Specifications

4.1 Sample weight: ≤ 500 g

4.2 Sample volume: ≤ 250 ml

4.3 Single vibration number: ≤ 99999 (Error less than 1 of 10000.

4.4 Motor torque: 0.86 N.m.

4.5 Frequency: Max. 300 rpm / min (continuous adjustable in 0-300 rpm)

4.6 Amplitude: maximum 15mm (1mm ~ 15 mm integer variable)

4.7 Repeatability: ≤ 1%.

4.8 Accuracy: ≤ 1%.

4.9 Power Supply: AC 200V ± 10% 50Hz, 40W.

4.10 Relative humidity: less than 85%, no condensation.

4.11 Other requirements: clean, smoke-free, dust-free, mechanical-vibration-free, electromagnetic- interference-free

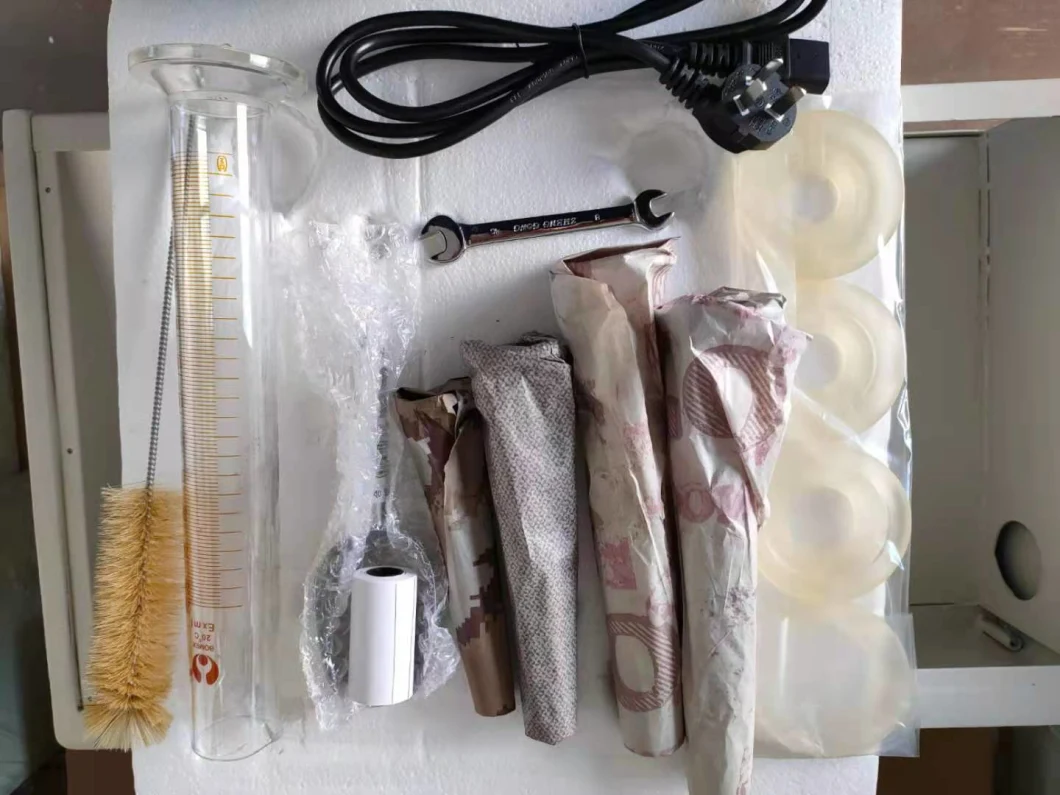

export carton or wooden case packing as following:

![]()